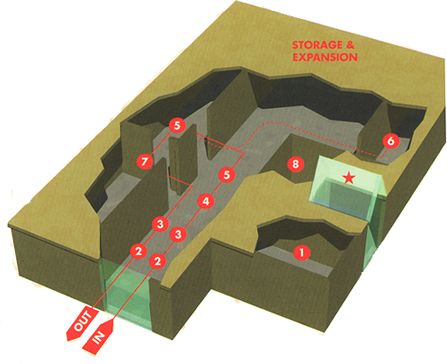

Efficient Product Flow is Critical to Quality, Precision Manufacturing of Hermetic Glass-to-Metal Seals

1 Engineering and Administration - Providing pre-production design support or post-production documentation, Northeast design and support capabilities will help to make your project with Northeast a quality experience.

2 Shipping and Receiving - Whether handling raw goods for your project or shipping finished products in Northeast's "Signature" packaging, quality and pride of workmanship are key to the handling of both inbound and outbound materials.

3 Inspection - Before entry into the system, all production materials are inspected and documented for quality control. Manufactured products are also inspected to rigorous standards numerous times during production and prior to shipment.

4 Assembly - With simultaneous production capabilities of many component jobs, the assembly area is centrally located to accommodate varied production processes.

5 Furnaces - Capable of component firing which requires pure gas batch furnaces, or more conventional belt furnaces, Northeast is equipped to handle the most exacting manufacturing requirements.

6 Machine Shop - A comprehensive machining facility, which includes welding, lapping, laser marking, grinding and other secondary operations, supports all production and custom furnace filtering.

7 Plating and Finishing - Complete with X-ray, chemical and microscopic analysis capabilities, Northeast's extensive plating and finishing area handles in-house plating in Copper, Tin, Nickel, and Gold.

8 Conference and Training Area - Equipped with a "floating wall", Northeast's conference and meeting area can accommodate multiple simultaneous customer meetings or work related training sessions.

* Tropical Rain Forest Atrium